ShopDreamUp AI ArtDreamUp

Deviation Actions

Star Wars models for DAZ

Images of available Star Wars models for your 3D rendering. Note that these are not downloads but, where possible, download links will be on the pages. Some are hi-res characters and clothing for G8 and G3 models, some are simple objects such as vehicles. I'm hoping this will be a fairly exhaustive look at both free and premium models available for Star Wars fans.

$10/month

Suggested Deviants

Suggested Collections

You Might Like…

Featured in Groups

Description

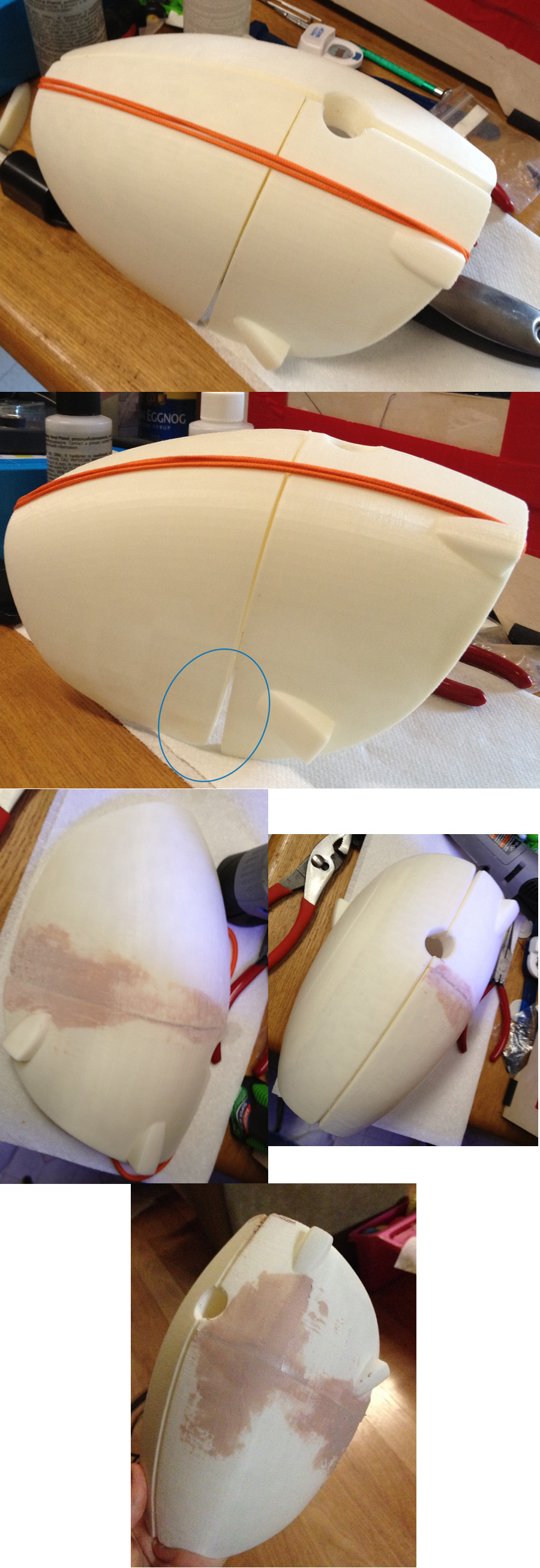

So the first half of the rear shell for the Portal Gun was printed as a single piece and used raft support to hold up the mass of it while the center line was flat on the platform.

It took over 26 hours to print, had a HUGE amount of wasted material for the support, and broke my makerbot.

<-- this piece.

<-- this piece.

Yup. It broke it. It was just too much wear and tear and the print nozzle got clogged, and one of the metal rods and support rubber things, came out of place.

After my husband spent an evening repairing the damage, we decided we needed to avoid anymore day-long prints.

However, we still needed to print the other half of the shell. It's the LAST frick'n piece to the gun!

So the solution I settled on was to split the shell in half so that the new slice down the middle could be the flat side that sits on the print platform.

This way it was exturding straight up the whole piece and didn't need ANY raft support at all.

No wasted material - much cleaner lines for the print, and it only took about 4-5 hours for each piece.

The downside, of course, is the fact that we would have to come up with some way to put the two sides together smoothly.

Thus - BONDO!

I'd never actually used it before, but it was recommended and so I gave it a shot.

HolycrapIlovethisstuff!

Seriously, Bondo is amazing. Love it.

My husband isn't so fond of the fumes, though. lol.

It's so smooth and it sands so nicely. Great stuff.

going to get some primer and paint this weekend.

In the 2nd pic above, I circled one of the areas I expected would give me the most trouble (and it did). Basically the flat sides where those two halves come together, are the sides that were on the print platform.

ABS plastic shrinks as it cools, so the stuff on the bottom layer sometimes has a tendency to 'curl' up off the platform as the bottom layer shrinks faster than the rest of it. These edges curled a bit and were no longer flat and flush against each other.

But the bondo filled it wonderfully. Yay.

It took over 26 hours to print, had a HUGE amount of wasted material for the support, and broke my makerbot.

<-- this piece.

<-- this piece.Yup. It broke it. It was just too much wear and tear and the print nozzle got clogged, and one of the metal rods and support rubber things, came out of place.

After my husband spent an evening repairing the damage, we decided we needed to avoid anymore day-long prints.

However, we still needed to print the other half of the shell. It's the LAST frick'n piece to the gun!

So the solution I settled on was to split the shell in half so that the new slice down the middle could be the flat side that sits on the print platform.

This way it was exturding straight up the whole piece and didn't need ANY raft support at all.

No wasted material - much cleaner lines for the print, and it only took about 4-5 hours for each piece.

The downside, of course, is the fact that we would have to come up with some way to put the two sides together smoothly.

Thus - BONDO!

I'd never actually used it before, but it was recommended and so I gave it a shot.

HolycrapIlovethisstuff!

Seriously, Bondo is amazing. Love it.

My husband isn't so fond of the fumes, though. lol.

It's so smooth and it sands so nicely. Great stuff.

going to get some primer and paint this weekend.

In the 2nd pic above, I circled one of the areas I expected would give me the most trouble (and it did). Basically the flat sides where those two halves come together, are the sides that were on the print platform.

ABS plastic shrinks as it cools, so the stuff on the bottom layer sometimes has a tendency to 'curl' up off the platform as the bottom layer shrinks faster than the rest of it. These edges curled a bit and were no longer flat and flush against each other.

But the bondo filled it wonderfully. Yay.

Image size

900x2613px 471.4 KB

Make

Apple

Model

iPhone 4S

Shutter Speed

1/20 second

Aperture

F/2.4

Focal Length

4 mm

ISO Speed

160

Date Taken

Aug 23, 2012 8:40:44 AM -06:00

© 2012 - 2024 Athey

Comments3

Join the community to add your comment. Already a deviant? Log In

where to find the 3d model for 3d printing

![DOWNLOAD: NATHAN DRAKE - full import [DOA5LR]](https://images-wixmp-ed30a86b8c4ca887773594c2.wixmp.com/i/1a4cf09f-1226-4d88-a762-449c7d51601b/daqlzbo-97c21098-37ee-45fd-98c4-51519ac5e60a.jpg/v1/crop/w_184)